It’s not every day you get to poke around inside the Ducati factory, and it’s even rarer to get an uncensored look at the most potent production bike motor they’ve ever made… the Desmosedici Stradale V4 R.

Whilst expected, the news of Ducati’s 2026 V4 R still landed as a welcome shock in our inbox, with the even bigger surprise being an invite to Bologna to get up close and personal with the 998cc V4 powerhouse, engineered to unleash a potential 239hp at 16,000rpm. The question was: what kind of witchcraft had they used to make such a mechanical feat possible?

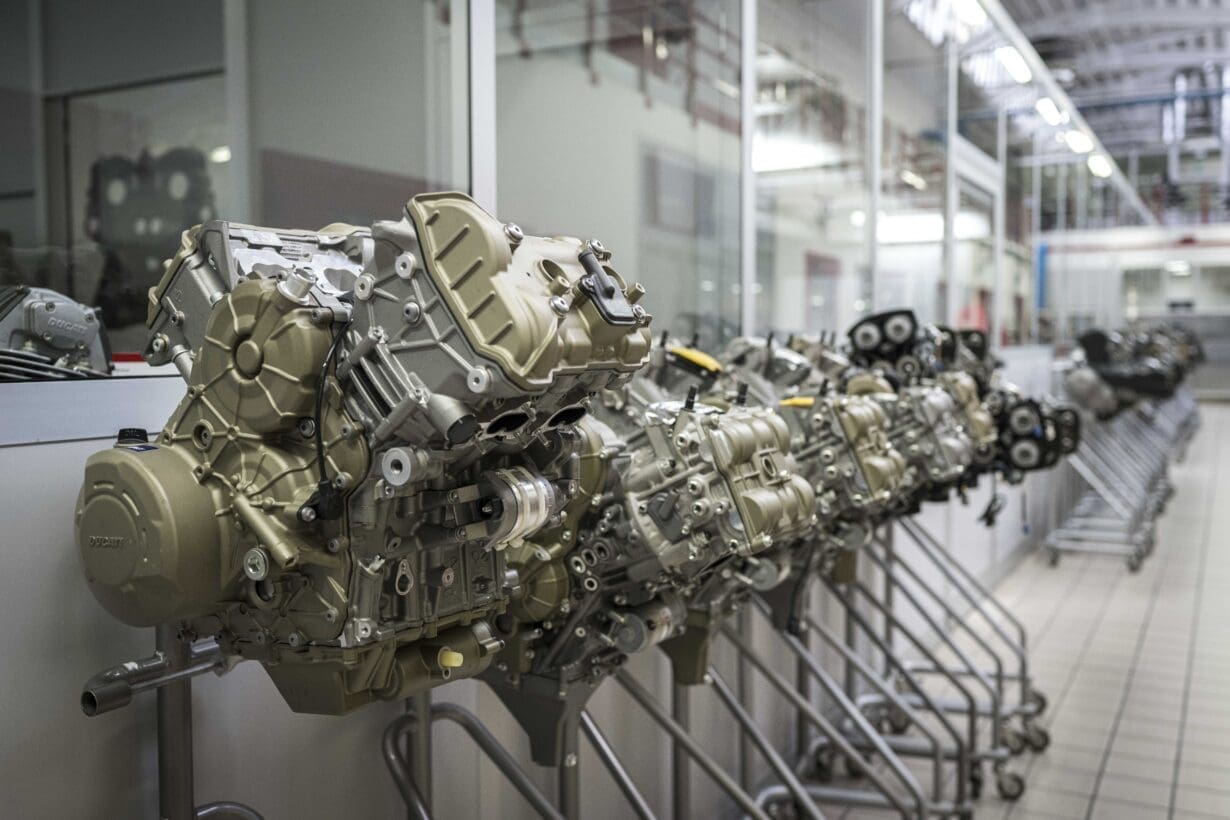

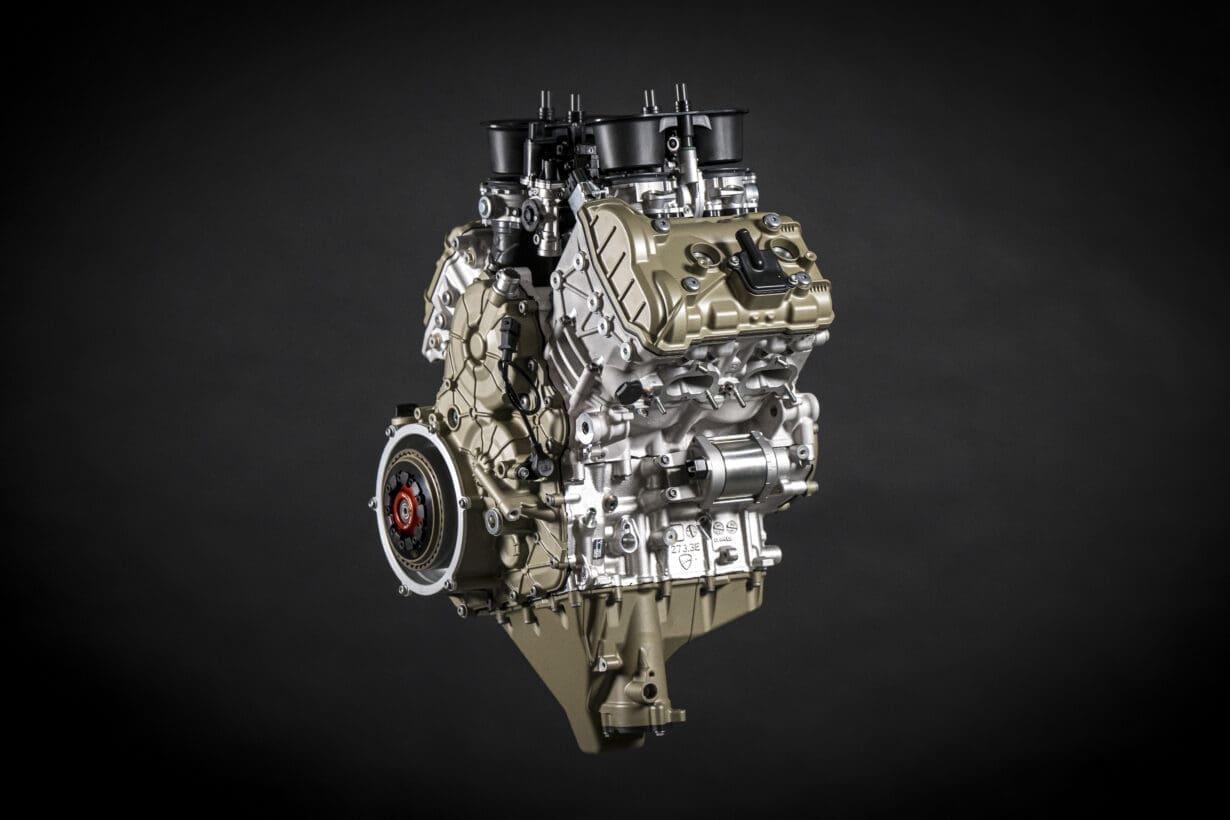

The Ducati V4 R engine isn’t just a lump of metal with moving parts – it’s a beast with character, a heart that defines the bike and sets new standards in the mesmerising world of performance engineering. At least, that’s how Ducati’s Head of Vehicle Testing described it to me in Bologna, whilst pulling the covers on the 2026 Desmosedici Stradale V4 R. Designed, developed and assembled right here in Italy, their V4 engine is a product that Ducati are deeply proud of. I learnt this firsthand as I spent the day with the Italian team, where they allowed me to open doors to some of the most exclusive parts of the Ducati Motor Holdings factory to see how their engines are developed as well as learn more about the new motor that will be pushed to the limit by World and British Superbike riders next year. Of course, the engine is just one part of the new, V4 R’s story, but it’s arguably the most pivotal component, packed full of pioneering design and unrivalled innovation. My first thought was that considering things are going quite well for Ducati, why is now the right time to bring out something new? How have they made something, that is already the best, even better? And I soon realised that Ducati didn’t just want to reveal a new V4 R that they’ve created; they wanted to tell the story and show with pride, how it was crafted.

Enjoy more Fast Bikes Magazine reading every month.

Click here to subscribe & save.

After years of being spell-bound as a kid and captured by the fascination of multiple machines lapping colourful circles on my television screen during a World Superbike race; to get the chance to visit Ducati HQ to see next year’s race engines in the flesh made me feel like Charlie at the chocolate factory. After being greeted with a friendly ‘Ciao, Grace’ and a generous slice of pizza in the factory canteen, this was shortly followed by a firm ‘nessuna foto’ – Italian for ‘no photos’ – as we were about to enter the engine testing department where engines for future production are developed; everything from their Desmo 250 MX engine to their 2026 MotoGP power-plant. I was even given stickers to cover up the lens on my iPhone just in case I tried to take a sneaky shot! It’s an extremely private and protected area, with it being the only place in the factory that requires you to have a pass to get in and out. Upon entering, rows of past engines welcome you into the depths of the department and leads to several test benches behind glass panels where prototype motors and components are mounted for performance and reliability checks. Preparation and homologation for every market is carried out here in Bologna, with data-collection and testing taking hundreds of hours and several years at a time. The testing division, of course, had a sanitary feel to it with plenty of computer screens, materials and wires hanging from the many corners, but what I was pleasantly surprised to see was that the area was also scattered with personal objects from the Ducati engineers that showed their passion for the project, such as signed merchandise, photographs and pieces of past MotoGP fairings stuck to the walls. The sophisticated test benches that the engineers were working on allow them to process information and change different parameters and components, so they understand the attitude of the engine and know how the bike will perform, which then allows them to calibrate a model of behaviour that they want to achieve. Particularly when it comes to racing. Simulations take place for different circuits, rider input and the team can perform different actuations like throttle response, braking and clutch control to gain an insight to reliability and attainment of both the engine and the gearbox. A process that the 2026 Desmosedici Stradale V4 R engine went through.

Claudio Domenicali, CEO – “We are very much an engineering driven company. We love racing and we are very passionate engineers. This V4 represents a milestone in the company. We used to be called the twin-cylinder engine company once upon a time and we were very famous for that, but actually once we started work on the V4, you can see how much the V4 has spread across our whole range, and we are very proud of this.”

In all their products, Ducati say that they apply their three core values; style, sophistication and performance. However, they believe there’s one particular product that represents these values more than others – their V4 engine. Ducati’s journey with the V4 started in 2017 when the Desmosedici Stradale engine was born and was fitted to the Panigale in 2018, which then evolved in 2019 into the racier Panigale V4 R. It was in 2019 that Ducati entered their first World Superbike and British Superbike Championships using a V4 motor. The Italian firm had plenty of success at World level with their V-twin configuration, lapping up success with the 888 in the 90s through to the 916, 996, 998, 999 to Carlos Checca taking victory in 2011 on the 1098R. I’m sure the dry spell of championship wins over the following decade had something to do with Ducati developing a brand-new Panigale that now flaunts a V4 as its beating heart. It was a seismic shift for Ducati; a move that needed to happen and took years of research and development but has already been rewarded with championship success at both British and World level. So, other than the obvious in that the V-twin wasn’t winning anymore, why else does that V4 set-up work so well in their flagship model and is the layout that continues to be used in their racing superbikes across the world for 2026?

Well, Ducati begin by saying that the reason they’ve chosen a V4 is mostly down to it being a better layout; the engine is narrower compared to an inline-4, which essentially helps package it better into the bike and gives them greater control over how to centralise the mass because the engine is more compact. This in turn also has a positive impact on the design of the aerodynamics. But what’s more is that thanks to the position of the cylinder heads, there’s convenient points for the frame to be attached which ultimately gives an efficient structure and allows the engine to be used as a stress member. This structure also gives another advantage over an inline-4 because regardless of its firing order, the 90° V4 is naturally more balanced against vibration compared to any inline engine, therefore reducing the need for any counterbalancing acts which would potentially mean an increase in weight and a decrease in performance. So, Ducati have made the argument that having a V4 base, gives them the space and creativity to develop a great engine but this is also the bike that’s the closest you’ll ever get to owning a Marc Marquez prepared MotoGP machine so it naturally makes sense to use the same configuration that’s found in their GP bikes so they can transfer technology directly from here to a street-legal weapon, then homologate it to go into their World Superbike effort.

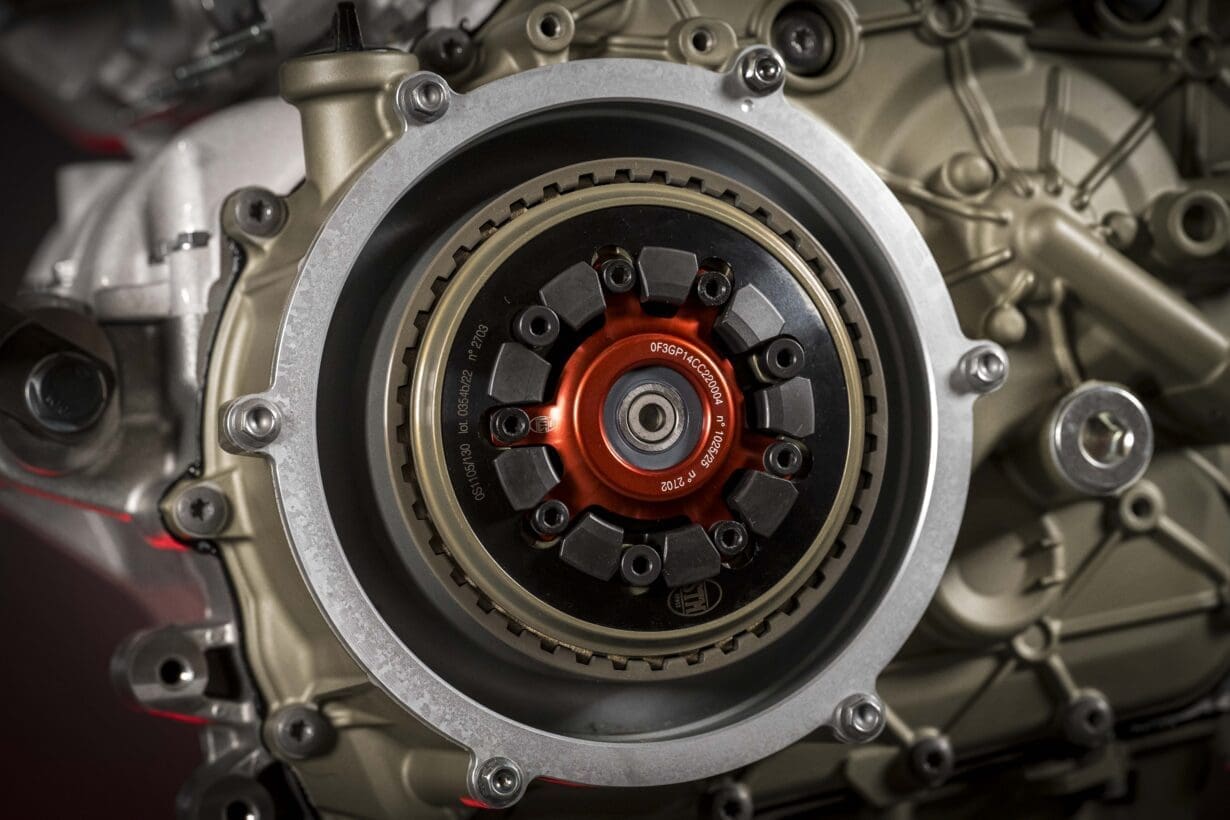

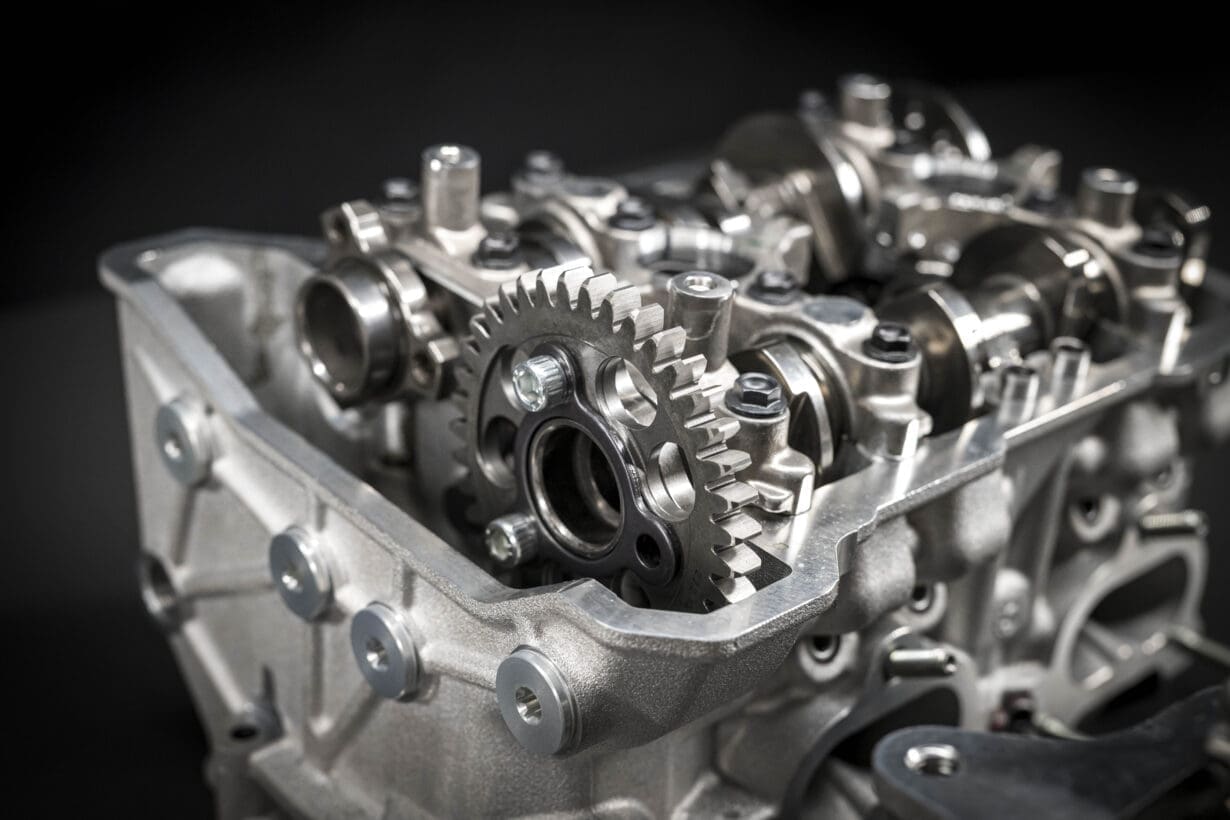

The cylinder head alone has exactly the same position for the camshaft, valves and ports that would be found in the current Desmosedici GP15 engine, albeit the GP engine can use more exotic materials and manufacturing processes. Other developments that have been directly transferred straight from MotoGP to this new engine include the same 81mm bore, a Twin Pulse firing order, that high-revving Desmo valvetrain, the fact the engine is in a backwards-rotated position and it now flaunts a counter-rotating crankshaft. The V4 R is also equipped with the compact dry clutch derived from the version used in their World Superbike by the official Ducati team. Compared to the clutch fitted on other V4 models, the diameter and axial length have been reduced by -24mm and the weight has been reduced by approximately 800g. My list of excuses for not setting a fast lap time are quickly reducing already. That book is soon to be thrown out the window anyway as the refinements made to the new V4 R keep coming at me, highlighting that this is a truly special piece of engineering. One of the reasons that makes this engine extraordinary is to do with that new counter-rotating crankshaft; a feature that is standard in MotoGP these days, but the new Desmosedici Stradale V4 R engine now showcases this making it the only production V4 with a counter-rotating crankshaft. Ducati are not shy in saying that this is an extremely complex solution for a production engine, however they were truly embracing the complexity as part of their ‘sophistication’ value. The biggest advantage is related to the inertial effects; every time you hard accelerate, the rear wheel has an inertial moment that wants to wheelie the bike and on the other side, when strong brakes are applied, the rear wheel decelerates and gives a force that wants to make the bike ‘stoppie’. Great for stunts but not fast laps. So, when the rotation of the crankshaft is the same direction as the wheels, it amplifies these effects but by having the crankshaft counter-rotating, it helps to reduce those stunt performances and enhance the stability of the bike. They assure me that the handling benefits are tangible because of the counter-rotation and that basically, it partially offsets the gyroscopic inertia of the wheels, ultimately enhancing the bike’s agility and manoeuvrability.

Vincenzo De Silvio, R&D Director – “Why didn’t we keep the V2 for our superbike? We have a very long heritage of a sporty V2, we developed the Superquadro engine a lot, which was a very powerful and very extreme engine but in the end we decided that in order to go further, we needed to move to a V4. The reason is that we understood if we wanted to get even more power for our Superquadro V2, we had to further increase the dimension of the bore and so consequently the dimensions and weight of the valves and this is a limiting factor for the acceleration that we can put into the valvetrain. The Desmosedici Stradale was able to reach much higher positive and negative accelerations and speeds than the Superquadro, with relevant benefits in terms of performance, right from the start. This is the reason why, even though we love the Superquadro engine.”

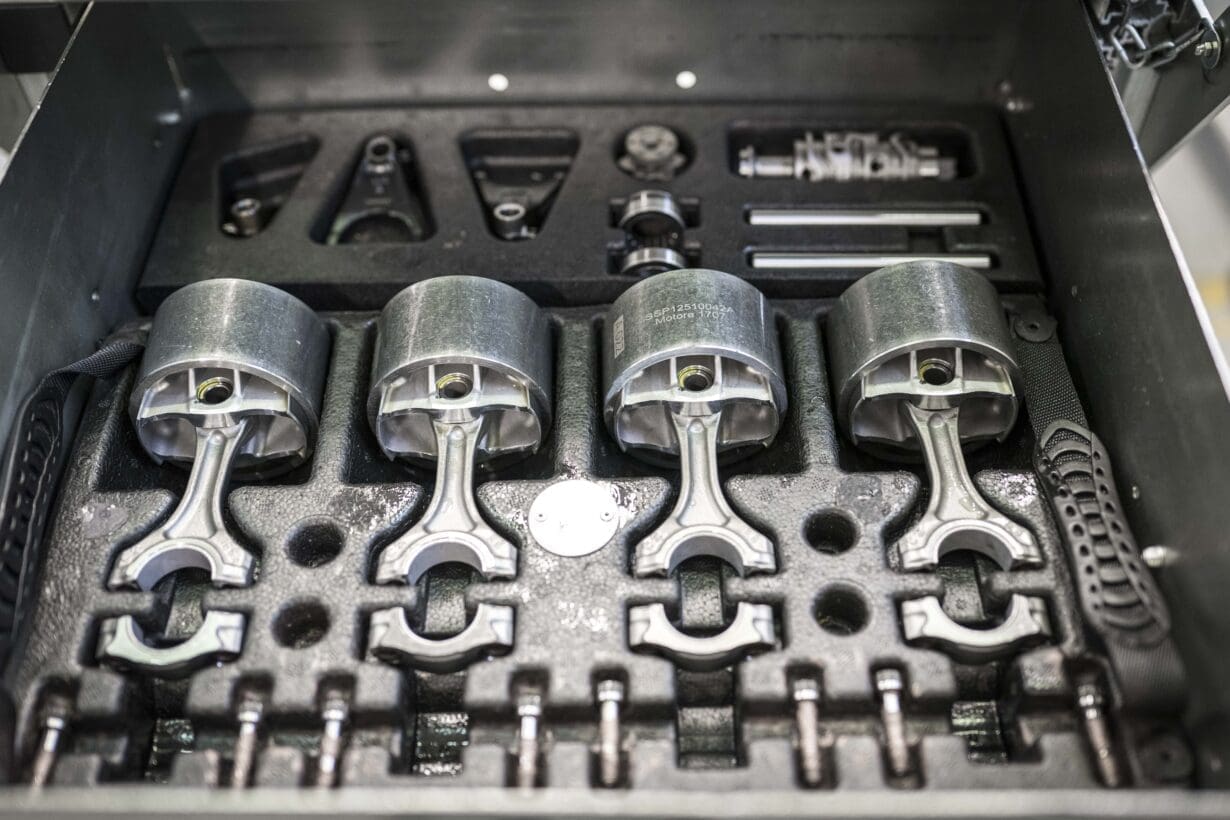

The 2026 Desmosedici Stradale still retains its 998cc displacement so it’s compliant to World Superbike regulations and it also keeps the twin-pulse firing order like the previous V4 R iteration. Aside from performance reasons, the twin-pulse touch feels like a subtle nod to their superbikes of the past that used a V2 configuration as it gives the engine some behaviour characteristics that are more V-twin-like, such as the sporty sound as well as a nice, linear torque curve. The “rough, raw, ‘typical Ducati’ sound” is something the R&D department say they really didn’t want to lose when moving from the V2 to the V4 and the twin-pulse firing order helps get close to that melody. As well as this, it’s among the firing orders that produce less secondary vibrations so it doesn’t require any kind of balancer shaft and also lowers the load and friction on the valvetrain, which therefore enables higher rpm. All good stuff. We also saw on the previous Desmosedici Stradale R engine that a lot of work had gone into improving the pistons which boasted a skirt finished in DLC (Diamond Like Carbon); a surface treatment used in MotoGP and also F1 racing, which essentially reduces the friction between the piston and the liner. On the 2023 V4 R, we saw this being applied for the first time to a road engine and it’s made a return for the 2026 version of their power house’s pistons. I was able to hold some example pistons from the Ducati production line and the DLC coating really is beautiful; silky to touch in a deep graphite colour and a luxurious finish as gleaming as lip gloss. But what is new about the pistons is that they’re even lighter, by 5.1% to be exact. The pistons are something that Ducati worked a lot on because, one of the main sources of friction inside the engine comes from the pistons and by lowering the weight also lowers the friction. To compliment this further, the MotoGP derived titanium conrods have also returned, again with the additional ‘gun drilled’ design, typical of a racing engine, and a ‘shot peened’ surface treatment which reduces the wear of the conrod.

But a huge battle for a racing engine is Euro5+ regulation. This engine needs to be compliant, so how have Ducati managed to achieve that same performance with those restrictions? Well, they’ve actually found more performance, which is some mind-boggling magic right there. For a start, they’ve completely re-designed the inlet manifold to allow a different position and angle of the port-fuel injectors. They now feature on the opposite side of the engine than before and by doing so has changed the length of the injector spray into the combustion chamber. Therefore, the throttle body design has also been changed with the throttle butterflies now rotating counterclockwise due to the new position of the injectors. These changes enable the air flow to mix more efficiently with the fuel spray pattern, producing a potent air-fuel mixture. Furthermore, shortened variable intake trumpets also feature on this engine, gaining valuable mid-range torque. Ducati have also changed the exhaust cam profile, which now allows the exhaust valve to open a little later. The aim of this new design being to improve the efficiency of the combustion, which helps both to increase torque and reduce emissions. The exhaust system has been completely redesigned and these new features help Ducati to comply with Euro5+. Despite the emission rules constantly being thrown at manufacturers, Ducati have come out laughing as they’ve found more torque whilst still playing the game. With these re-designed aspects, they’ve managed to increase the torque in a wide range of engine speed, whilst still achieving the same peak power as the previous version, but now being Euro5+ compliant. To give some specifics, this engine is up +4hp at 16,000 rpm, has 7% more torque at 6,000 rpm and has an increase of 3% of peak torque. This gives an average of 4hp more between 8,000 – 16,000rpm and ultimately greater regularity at low revs and during acceleration above 7,000 rpm, delivering stronger torque and power curves over the entire working range and better over-rev capabilities than the 2023 Desmosedici Stradale engine. What does this mean? Essentially this will give the rider more pull from the engine in the most usable range of speed on track and gives that incredible feeling of drive when you twist your wrist. There’s even more to be had too if you decide to utilise the Akrapovič performance racing exhaust system, saving 6.6kg in weight, and use the ‘Ducati Genuine Oil Powered by Shell Advance’ which results in even stronger torque and power curves over 9,000 rpm, peak power is up + 17.3hp @15,750rpm and peak torque is up + 5Nm @ 12,000rpm.

The finishing touch in making you feel like the ultimate superbike rider, is that the Italian firm have introduced their Ducati Racing Gearbox (DRG) with Ducati Neutral Lock (DNL) for the first time on a production, homologated motorcycle; another learning taken straight from their MotoGP experience and given to the handlebars of the new V4 R. The device, shortened in name to ‘DRG’, has the neutral position below the first gear, instead of between first and second – just like it would be found on their MotoGP and factory superbikes. The aim of this feature is to prevent the rider accidentally clicking ‘neutral’ when changing gear from first to second or second to first. Ducati explained their awareness of the dangers if a rider enters neutral, as this would lose any engine braking. If ever it’s happened to you on track or out on the road, it’s not a nice feeling when the green N flashes on the dash and a handful of unhappy screams proceeds from the engine. But aside from making it safer, it’s also quicker to shift between the lowest gears. So, Ducati have modified the gear sequence and inserted a mechanical pinlock (DNL) that blocks the rotation of the gear drum. In order to select neutral, you have to push on a lever on the right-side of the handlebar to enable the drum to enter neutral; and when you want to go from neutral to first, you click the foot lever as normal. Pecco Bagnaia style.

So, in summary Ducati have thrown every trick up their sleeve at the new 2026 Desmosedici Stradale V4 R engine, delivering a maximum power of 239hp in its track configuration, as well as a few gadgets and gizmos along the way to make the delivery smoother, lighter and more agile. All of this, to ensure they say ahead of the competition. This engine insight has confirmed to me that, Ducati want to be the best and remain the best. So rather than waiting for someone else’s benchmark to beat, they’re competing with their own. Constantly pushing the boundaries of what’s possible at their Bologna base, seeking innovative solutions and striving for style and sophistication to shine through in their performance. Weekly developments from their racing programmes inform their road-going versions, ultimately allowing more riders to enjoy the sensation of their assiduous engineering from their diligent teams and what they’ve crafted is a masterpiece in machinery. And that’s just to the engine. As already mentioned, there’s a whole new bike to further compliment this project, and we cannot wait to see it out on track, as well as the lavish, numbered bikes that will be taking to the streets in 2026.